How Precision Machining Powers Innovation in Medical Devices

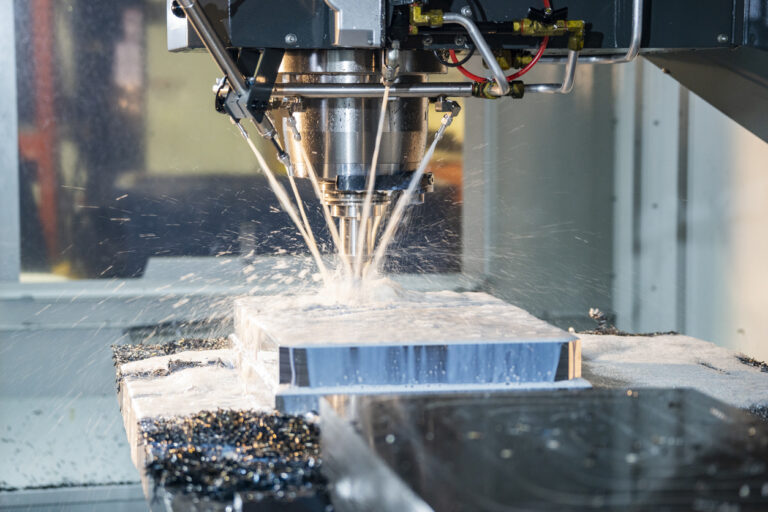

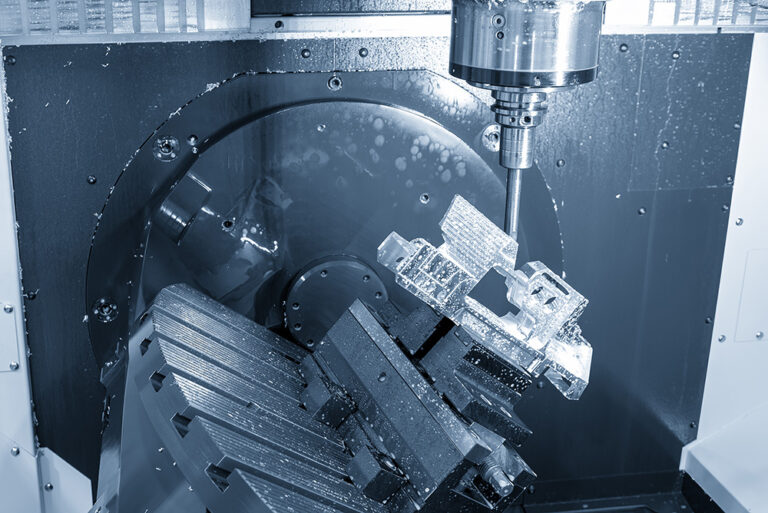

From the surgical tools used in operating rooms to the implants and diagnostic equipment that save lives, precision machining is the foundation of reliable, high-performance medical device components. These parts must not only meet strict dimensional requirements but also deliver consistent results in mission-critical applications, where even the smallest deviation can make a life-changing difference.