Bringing a new product to life is rarely a straight line. The transition from early prototype to full-scale production is where many promising ideas slow down or stall entirely. Design revisions pile up. Materials behave differently than expected. Machining tolerances tighten. Supply chains introduce delays. Repeatability becomes a concern just as demand begins to rise. For product teams under pressure, these hurdles directly impact time-to-market.

This is where DPI steps in, not simply as a machine shop, but as a true manufacturing partner that supports the entire product development lifecycle.

Why Prototype-to-Production Is So Challenging

Most delays happen at the seams between design, engineering, and manufacturing. A prototype may look great on paper or perform well in testing, but still fall short when it’s time to scale. Common bottlenecks include design features that are difficult to machine consistently, material choices that drive cost or lead time, and limited visibility into how parts will behave in production volumes.

Without early manufacturing input, teams often face rework, scrap, and last-minute design changes that push launches back by months. DPI’s approach is built to prevent those issues before they appear.

Early Engineering Collaboration That Prevents Downstream Problems

DPI works as an extension of the customer’s engineering team from the very beginning. During early prototype stages, DPI provides rapid prototyping services alongside design-for-manufacturability guidance. This collaboration ensures designs are optimized not only for performance, but also for production efficiency, consistency, and long-term scalability.

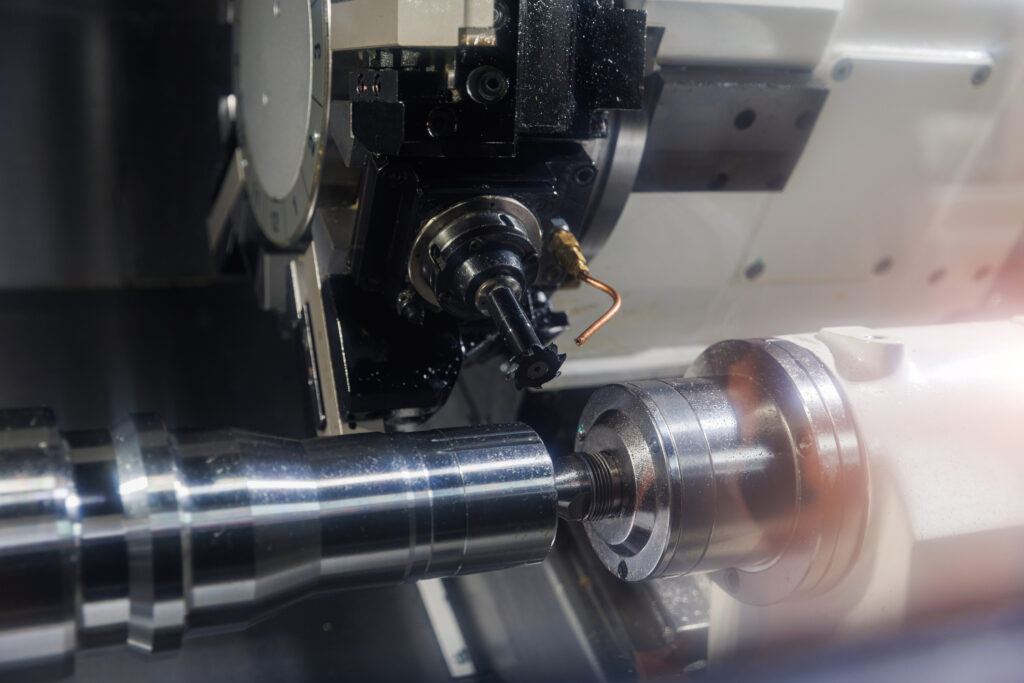

Design-for-manufacturability is more than simplifying geometry. It involves evaluating tolerances, material availability, tooling strategy, and machining methods such as 5 axis milling, CNC milling, or CNC turning service selection. These decisions have a direct impact on cost, lead time, and reliability once production ramps up.

By addressing these factors early, DPI helps customers avoid redesign cycles that slow time-to-market and inflate budgets.

Iterative Prototyping That Builds Toward Production-Ready Design

Prototyping isn’t a single step. It’s an iterative process that bridges concept and production. DPI supports this evolution by machining prototypes using the same processes and equipment that will be used in full-scale manufacturing. This approach allows product teams to validate form, fit, and function under realistic production conditions.

Whether a project involves complex geometries, tight tolerances, or specialized applications like CNC machining for cryogenics, DPI’s machining capabilities ensure prototypes accurately reflect production intent. As designs mature, DPI seamlessly transitions projects into contract manufacturing, maintaining continuity across every phase.

This continuity reduces handoff errors and accelerates the overall prototype to production transition.

Precision Machining and Scalable Manufacturing Solutions

Once a design is production-ready, DPI’s precision CNC machining infrastructure supports efficient scaling without sacrificing quality. From low-volume initial runs to higher-volume production schedules, DPI applies consistent process control and documented workflows to ensure repeatability.

Advanced machining strategies, including custom CNC machining, cryogenic machining, and multi-axis operations, allow DPI to support demanding applications across industries. Integrated supply chain support services and value-added operations further reduce coordination complexity for customers, keeping timelines tight and predictable.

This scalability is critical for companies looking to accelerate time-to-market while preparing for long-term growth.

Quality Assurance That Protects Launch Timelines

Production delays often stem from quality failures discovered too late. DPI’s robust quality assurance systems are designed to catch issues early and maintain confidence as production scales. In-process inspection, final verification, and traceability are built into the workflow—not treated as afterthoughts.

This focus on precision manufacturing quality supports faster approvals, fewer nonconformances, and smoother customer acceptance. For regulated and high-risk industries, DPI’s quality discipline directly protects launch schedules and brand reputation.

Mini-Scenarios Across High-Impact Industries

In aerospace and national defense, DPI supports components with strict tolerance, documentation, and traceability requirements, enabling OEMs to move from prototype validation into compliant production programs without disruption.

In medical and cryogenics applications, DPI helps teams refine production-ready designs that perform reliably in extreme or regulated environments, minimizing delays tied to material behavior or machining constraints.

In oil and gas and advanced industrial applications, DPI’s early supplier involvement reduces cost and timeline risk by aligning machining strategy with real-world operating conditions.

Across each scenario, the result is the same: faster transitions, fewer surprises, and shorter time-to-market.

A Manufacturing Partner Built for Speed and Stability

From first concept to final production run, DPI provides engineering and machining support that evolves with each project stage. This collaborative approach transforms manufacturing from a bottleneck into a competitive advantage.

By combining rapid prototyping, design-for-manufacturability expertise, precision CNC machining, scalable production, and disciplined quality systems, DPI Inc. helps product teams move confidently and efficiently from idea to impact.

To explore DPI’s full machining capabilities or start a new project, visit the Services & Capabilities page or submit files directly through the RFQ & File Transfer portal.