When industries like aerospace, defense, and energy depend on your parts, there’s no room for error. Every cut, every tolerance, every finish must meet exacting standards. That’s why at DPI, quality assurance isn’t an afterthought, it’s the foundation of our entire operation.

By combining advanced machining technologies, rigorous inspection processes, and strict certifications, DPI ensures that every project we deliver meets or exceeds the performance requirements of mission-critical applications.

What Quality Assurance Means at DPI

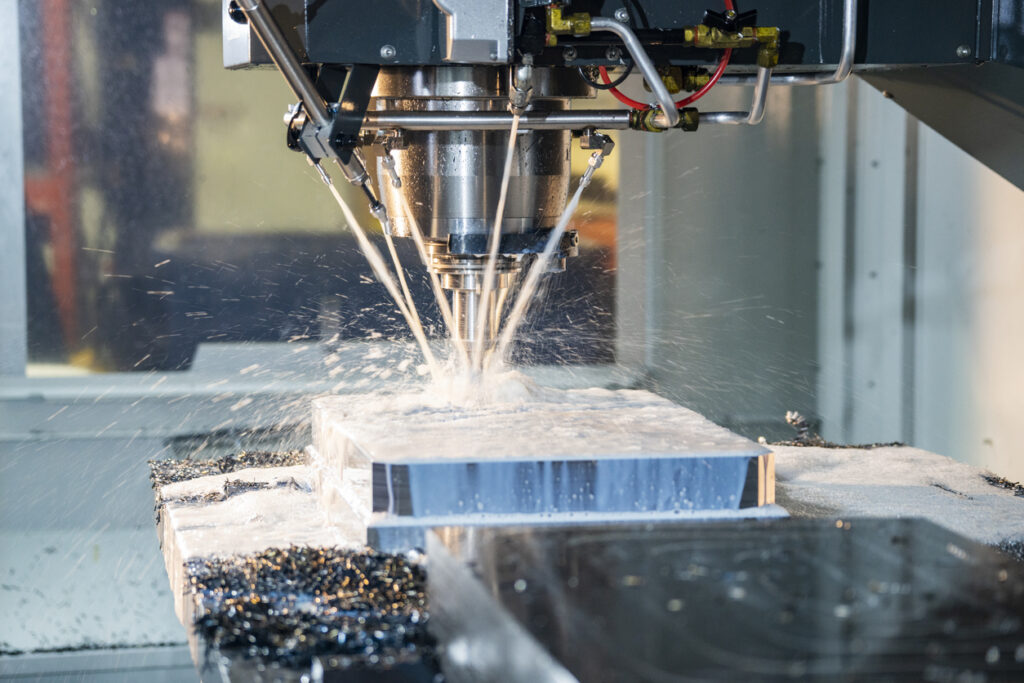

At its core, quality assurance is the guarantee that every part is built to specification, no shortcuts, no compromises. From CNC milling and CNC turning services to specialized cryogenic machining, DPI employs industry-leading methods to maintain precision and repeatability.

Our processes are guided by documented quality management systems and verified through cutting-edge inspection equipment. This ensures every part not only meets dimensional tolerances but also aligns with the safety and performance demands of high-stakes industries.

Certifications That Build Confidence

When selecting a contract manufacturing partner, certifications matter. They demonstrate consistency, traceability, and compliance with global standards. At DPI, our certifications validate our ability to serve regulated industries such as aerospace, defense, and medical. These certifications go beyond paperwork, they represent decades of investment in people, processes, and technology to support the most demanding customers.

For Original Equipment Manufacturers (OEMs), this means peace of mind knowing their supply chain is backed by partners with proven systems of accountability.

Inspection Processes that Leave Nothing to Chance

Every part at DPI undergoes rigorous inspection using advanced metrology tools. From Coordinate Measuring Machines (CMMs) to high-resolution optical systems, our inspection team verifies dimensions, surface finishes, and material integrity.

This attention to detail is especially critical when producing complex geometries through methods such as 5-axis milling. Intricate cuts, tight angles, and thin walls demand not only advanced machining capabilities but also the ability to prove accuracy at every step. Our inspection processes ensure no deviation goes unnoticed.

Advanced Machining for Specialized Needs

Mission-critical industries often demand parts that push the limits of materials and design. DPI meets these challenges head-on with specialized machining services:

- CNC milling and CNC turning for versatile, high-precision part production.

- Cryogenic machining for extreme environments, where CNC machining for cryogenics ensures parts perform reliably at ultra-low temperatures.

- Custom CNC machining solutions designed to accommodate unique OEM requirements, from prototype to production scale.

- 5-axis milling for producing complex geometries with a single setup, increasing accuracy and reducing production time.

Together, these machining capabilities allow us to support projects with tight tolerances, unusual materials, and high-performance demands.

Supply Chain and OEM Support Services

Quality assurance extends beyond machining. OEMs and contractors require full lifecycle support, from prototype through production, packaging, and logistics. DPI’s supply chain support services ensure parts arrive when and where they’re needed, without disruption.

Our OEM support services also include engineering collaboration, documentation, and scalable production to match evolving demand. This integrated approach makes us more than a machining shop, we’re a reliable partner in your supply chain.

Why Quality Assurance Matters for Mission-Critical Industries

In regulated industries, failure isn’t just costly, it can be catastrophic. A single component out of spec can lead to system failure, safety risks, and regulatory setbacks. By prioritizing quality assurance, DPI gives customers:

- Reliability: Confidence that parts perform under the harshest conditions.

- Compliance: Alignment with industry and government standards.

- Traceability: Documentation at every stage, from raw material to finished product.

- Performance: Precision machining ensures every part meets its intended function.

Partnering with DPI

Whether you need contract manufacturing, prototype development, or full-scale production, DPI’s commitment to quality provides assurance that your project will meet the highest standards. Our customers trust us because we’ve proven our ability to deliver precision parts that stand up to scrutiny and performance testing in the most demanding industries.

Explore our quality assurance processes, learn more about our industries served, or review our services and capabilities.

When you’re ready to discuss your project, contact us or submit an RFQ. DPI is ready to prove that true quality assurance is more than a promise, it’s a process we live by every day.